Tips on how to calculate bolt yield power is essential in engineering. Understanding this very important side ensures the security and reliability of constructions and machines. This information delves into the intricacies of figuring out bolt yield power, exploring the underlying ideas and sensible purposes.

From defining bolt yield power and its significance in engineering purposes to exploring varied elements influencing its worth, this information is an entire useful resource. We’ll cowl strategies for calculating yield power, sensible purposes, and illustrative examples to solidify your understanding.

Introduction to Bolt Yield Energy

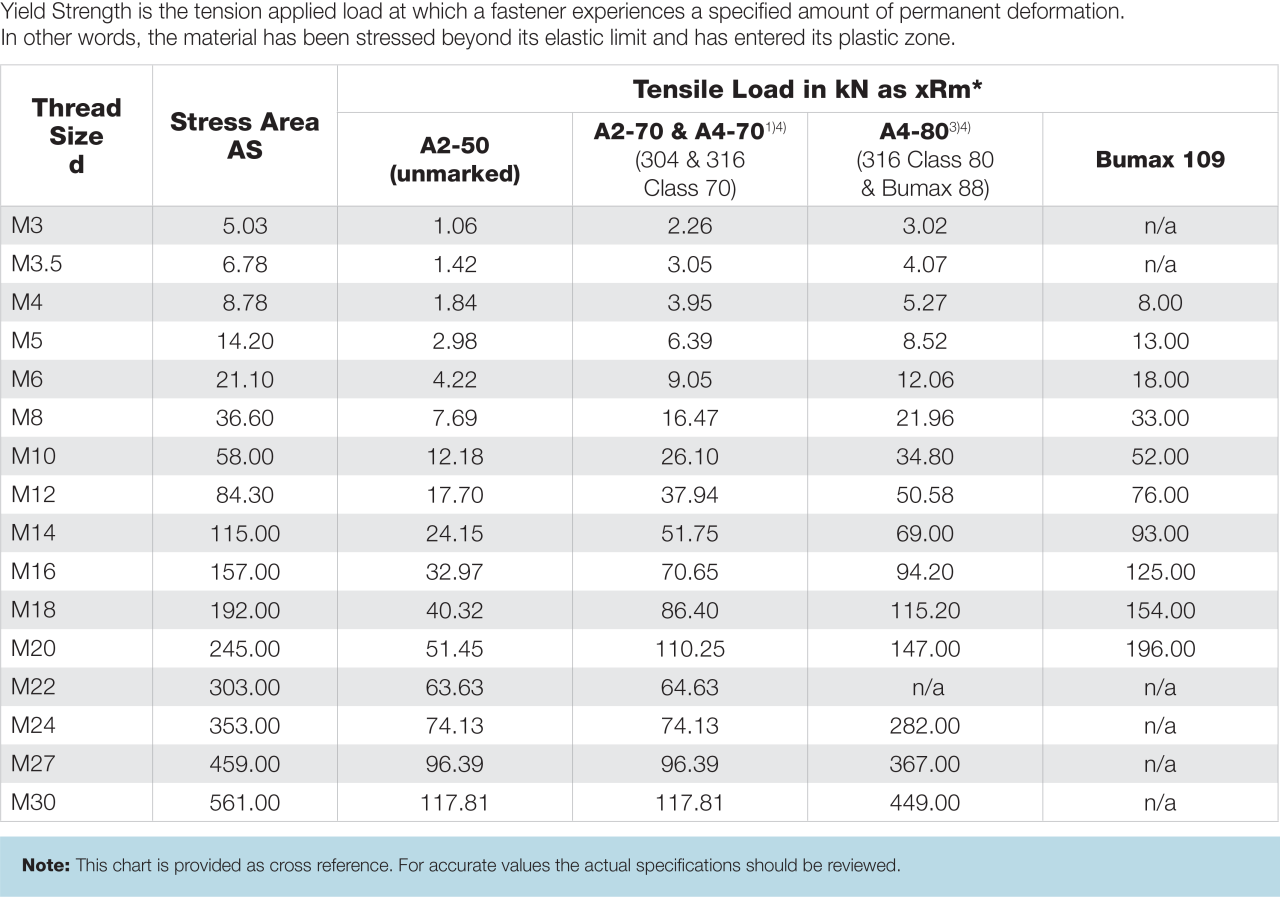

Bolt yield power is a essential materials property that dictates a bolt’s capability to resist stress with out everlasting deformation. Understanding this property is paramount in engineering design, making certain structural integrity and stopping catastrophic failures. A exact calculation of bolt yield power is crucial for engineers to pick acceptable bolts for varied purposes, guaranteeing security and reliability. It isn’t nearly numbers; it is about making certain the parts of a machine, a bridge, or perhaps a easy fixture can deal with the anticipated hundreds.The importance of understanding bolt yield power extends to a number of essential points of engineering design.

Correct calculation permits engineers to pick bolts with adequate power to endure anticipated stresses, minimizing the chance of failure. This, in flip, enhances the security and reliability of the complete construction or machine. Furthermore, understanding yield power permits for optimum part design, decreasing materials waste and enhancing total effectivity. An intensive understanding of bolt yield power is a key aspect within the arsenal of each mechanical engineer.

Materials Properties and Bolt Yield Energy

Materials properties play a pivotal position in figuring out the yield power of a bolt. Totally different supplies exhibit various responses to emphasize, resulting in totally different yield strengths. Components like alloy composition, warmth remedy, and manufacturing processes all contribute to the last word yield power a bolt can obtain. Engineers should meticulously contemplate these elements to pick the suitable materials and make sure the calculated yield power aligns with the meant utility.

As an example, a high-strength metal bolt could have the next yield power in comparison with a gentle metal bolt, making it appropriate for purposes requiring higher load-bearing capability.

Frequent Bolt Sorts and Their Typical Yield Energy Ranges

Deciding on the suitable bolt kind is essential for a design. This selection is immediately linked to the anticipated load and the specified security margin. Totally different bolt varieties have totally different typical yield power ranges, and it is important for engineers to know these ranges. This data permits for knowledgeable selections relating to the bolt’s suitability for particular purposes.

| Bolt Sort | Typical Yield Energy Vary (MPa) |

|---|---|

| Carbon Metal Bolts (Grade 5) | 350-550 |

| Alloy Metal Bolts (Grade 8) | 600-850 |

| Excessive-Energy Metal Bolts (Grade 10.9) | 850-1050 |

| Stainless Metal Bolts | 200-1200 (relying on alloy) |

The desk above gives a common guideline. Particular yield strengths might differ primarily based on the producer, particular alloy composition, and manufacturing course of. Engineers ought to all the time seek the advice of the producer’s specs for exact values.

Components Affecting Bolt Yield Energy: How To Calculate Bolt Yield Energy

Bolt yield power, an important parameter in structural engineering and mechanical design, is not a static worth. It is influenced by a large number of things, making a radical understanding important for secure and dependable purposes. This part delves into the important thing components that form the yield power of bolts, enabling knowledgeable selections in engineering initiatives.Understanding these elements permits engineers to pick the suitable bolt materials and design parameters to make sure the bolt can face up to the anticipated hundreds with out yielding.

This meticulous evaluation is paramount for structural integrity and security.

Materials Composition

Materials composition considerably impacts the yield power of bolts. Totally different metal grades exhibit various strengths. Carbon content material, alloying components, and the presence of impurities all contribute to the last word power and ductility of the bolt materials. As an example, larger carbon content material typically ends in larger yield power however may lower ductility. Alloying components like chromium, molybdenum, and vanadium can considerably improve power and hardenability, enhancing resistance to deformation.

Understanding the exact composition of the metal is essential in choosing the suitable bolt for a selected utility.

Warmth Remedy Processes

Warmth remedy processes play a pivotal position in modifying the microstructure of the bolt materials, thus influencing its yield power. Totally different warmth remedies, reminiscent of annealing, quenching, and tempering, alter the grain measurement and distribution of phases inside the materials. Quenching, adopted by tempering, is continuously used to extend the yield power and hardness of metal bolts. This rigorously managed course of results in a stronger, extra resilient bolt able to withstanding larger stresses.

The precise warmth remedy parameters, together with temperature and time, immediately have an effect on the ultimate mechanical properties of the bolt.

Manufacturing Processes

Manufacturing processes, together with forging, casting, and chilly heading, additionally have an effect on bolt yield power. Forging, a strategy of shaping steel beneath excessive stress and temperature, can result in a extra uniform microstructure and improved mechanical properties, leading to larger yield power in comparison with casting. Chilly heading, a strategy of shaping steel at room temperature, may improve power however might result in elevated residual stresses.

The number of the suitable manufacturing course of is determined by the specified yield power, price concerns, and the particular utility of the bolt.

Bolt Dimensions

Bolt dimensions, reminiscent of diameter and size, considerably influence the yield power. A bigger diameter bolt sometimes reveals the next yield power because of the elevated cross-sectional space, which might higher face up to tensile forces. Equally, the size of the bolt can have an effect on the stress distribution and potential for localized yielding. Longer bolts could also be extra inclined to bending or yielding beneath excessive hundreds, requiring cautious consideration of stress concentrations and design parameters.

Yield Energy Comparability of Metal Grades

| Metal Grade | Typical Yield Energy (MPa) |

|---|---|

| ASTM A307 | 250-300 |

| ASTM A325 | 827-1034 |

| ASTM A490 | 1034-1241 |

| AISI 1018 | 290-360 |

| AISI 1045 | 480-580 |

This desk gives a concise overview of the standard yield strengths related to totally different metal grades generally utilized in bolts. Notice that these values are approximate and may differ primarily based on particular manufacturing processes and testing circumstances.

Strategies for Calculating Bolt Yield Energy

Unveiling the secrets and techniques of bolt yield power requires a deep dive into the strategies used to find out this important materials property. Correct calculation is crucial for making certain the structural integrity and longevity of bolted connections in varied engineering purposes. This part will illuminate the method, from conducting tensile checks to deciphering stress-strain curves, and can spotlight the requirements that information these calculations.Understanding bolt yield power is paramount to engineering design.

An intensive understanding of the strategies used to find out this worth permits engineers to decide on acceptable supplies and design sturdy and dependable constructions. It ensures security margins are met and prevents potential failures.

Tensile Check Methodology

The tensile take a look at technique is a cornerstone in figuring out the yield power of bolts. It entails subjecting a rigorously ready bolt specimen to a managed tensile load, measuring the ensuing elongation. This course of gives invaluable knowledge for characterizing the fabric’s response to emphasize.

Process for a Tensile Check on a Bolt Specimen

An ordinary tensile take a look at process is rigorously adopted. A exactly machined bolt specimen is secured in a testing machine. The machine applies a progressively rising tensile load whereas concurrently recording the corresponding elongation. The load and elongation knowledge are meticulously logged at common intervals. This systematic method ensures dependable and repeatable outcomes.

Calibration of the testing machine is essential for accuracy.

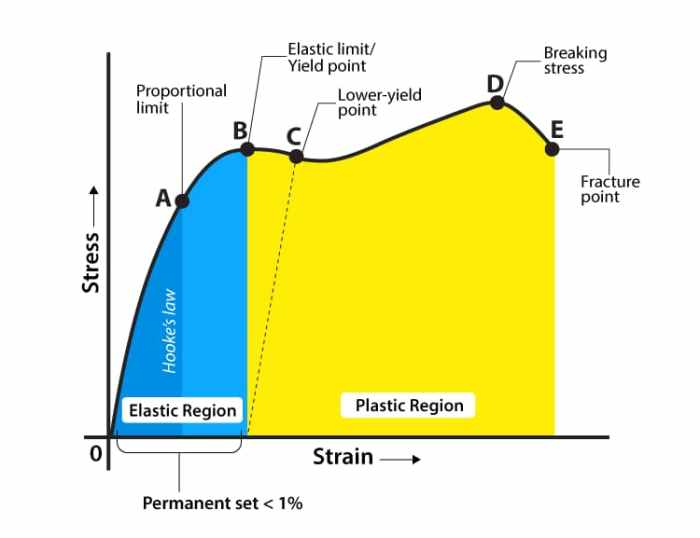

Stress-Pressure Curves and Yield Energy Identification

A stress-strain curve is a graphical illustration of the connection between stress and pressure. This curve is essential for figuring out the yield power. The yield power is the stress degree at which the fabric begins to deform plastically. Visually, this level is commonly recognized by the onset of a noticeable deviation from the linear elastic portion of the curve.

The purpose of yielding is commonly marked by a noticeable change in slope on the curve. The stress worth corresponding up to now is the yield power.

Requirements and Specs

Quite a few requirements and specs govern the calculation of bolt yield power. These requirements, like ASTM (American Society for Testing and Supplies) and ISO (Worldwide Group for Standardization), dictate the procedures for conducting tensile checks, reporting knowledge, and defining particular phrases associated to materials properties. These requirements are important to make sure constant and dependable outcomes throughout totally different laboratories and industries.

ASTM A325 and ISO 898 are widespread examples.

Calculating Bolt Yield Energy from Materials Properties

After a tensile take a look at, the yield power might be calculated utilizing the method derived from the stress-strain curve. The calculation entails figuring out the stress worth similar to the yield level. The method is a basic relationship between stress, drive, and space. The yield power is then decided from the measured drive and the cross-sectional space of the bolt specimen.

For instance, if the drive at yield is 10,000 Newtons and the cross-sectional space is 10 sq. millimeters, the yield power is 1000 MPa.

Desk of Testing Requirements and Calculation Strategies

| Testing Customary | Calculation Methodology |

|---|---|

| ASTM A325 | Tensile take a look at following ASTM A325 procedures. Yield power is decided from the stress-strain curve, particularly the offset technique or the 0.2% offset technique. |

| ISO 898 | Tensile take a look at following ISO 898 procedures. Yield power is decided from the stress-strain curve, utilizing the offset technique or the proof stress technique. |

| Different Particular Requirements | Particular requirements might have distinctive calculation strategies or specs for various bolt varieties and supplies. |

Sensible Purposes and Concerns

Unlocking the secrets and techniques of bolt yield power is essential for making certain the security and reliability of numerous engineering marvels. Understanding easy methods to calculate and apply this essential parameter empowers engineers to design sturdy constructions and equipment, mitigating the chance of catastrophic failure. This part dives into sensible purposes, emphasizing the significance of security elements, preload, and fatigue concerns in bolt design.Bolt yield power is not only a theoretical idea; it is a cornerstone of structural integrity.

By understanding its implications and making use of acceptable calculations, engineers can confidently design parts that face up to anticipated hundreds and environmental stresses, making certain the longevity and efficiency of the programs they create.

Bolt Yield Energy in Structural Design

Bolt yield power is key to structural design, notably in purposes involving pressure, shear, and mixed loading. Engineers should contemplate the yield power to find out the utmost load a bolt can face up to earlier than everlasting deformation happens. This significant information prevents structural failure and ensures the security of the complete system.

Examples of Calculating Bolt Yield Energy

Quite a few engineering purposes depend on correct bolt yield power calculations. In bridge building, for instance, calculating the yield power of bolts becoming a member of the principle girders is significant for making certain the bridge’s structural integrity beneath varied load circumstances. Equally, in plane design, exact yield power calculations for bolts connecting parts are paramount for making certain the plane’s structural integrity and security throughout flight.

Within the automotive business, correct yield power calculations for engine mounting bolts are essential to forestall engine failure.

Significance of Security Components in Bolt Design

Security elements are indispensable in bolt design. They account for uncertainties in materials properties, loading circumstances, and manufacturing tolerances. A security issue, sometimes higher than 1, is utilized to the calculated yield power to make sure that the bolt can face up to the next load than predicted by calculations alone. This margin of security prevents untimely failure because of unexpected circumstances.

As an example, a security issue of 1.5 utilized to a bolt with a yield power of 100 MPa would imply the bolt is designed to resist a load of 150 MPa.

Bolt Preload and its Impact on Yield Energy

Bolt preload is the preliminary pressure utilized to a bolted joint. This pressure considerably impacts the bolt’s final power and load-carrying capability. By preloading bolts, engineers can enhance the joint’s stiffness and sturdiness. A correctly preloaded bolt experiences the next yield power in comparison with a bolt with out preload. It’s because the preload successfully will increase the preliminary stress within the bolt, which should be exceeded earlier than the bolt yields.

Fatigue Failure in Bolts and its Relation to Yield Energy

Fatigue failure, a typical mode of failure in bolts, happens because of repeated stress cycles exceeding the fabric’s endurance restrict. Bolt yield power performs an important position in fatigue evaluation, because it determines the stress vary that may trigger failure. A bolt with the next yield power can typically face up to extra stress cycles earlier than fatigue failure.

Accounting for Bolt Geometry in Calculations

Bolt geometry, together with diameter, size, and thread configuration, considerably influences the bolt’s load-carrying capability. Engineers should account for these elements when calculating bolt yield power. Totally different geometric configurations will have an effect on the stress distribution and the last word power of the bolt. Subtle evaluation strategies, typically utilizing finite aspect evaluation (FEA), can precisely mannequin the stress distribution and supply extra exact yield power estimations, particularly for advanced geometries.

Desk Evaluating Security Components

| Engineering Software | Typical Security Issue |

|---|---|

| Bridge Building | 1.5 – 2.0 |

| Plane Design | 2.0 – 3.0 |

| Automotive Elements | 1.2 – 1.8 |

| Strain Vessels | 2.5 – 4.0 |

This desk gives a common overview of typical security elements utilized in varied engineering purposes. These values usually are not absolute and may differ primarily based on particular design standards, materials properties, and the extent of danger tolerance.

Illustrative Examples

Unleashing the facility of calculation, we’ll now delve into sensible examples of figuring out bolt yield power. These eventualities illustrate easy methods to apply the theoretical information to real-world engineering issues, highlighting the essential position of correct yield power estimations.

Bolt Yield Energy Calculation for a Particular Bolt Sort

Calculating the yield power of a selected bolt kind entails a scientific method, contemplating materials properties and loading circumstances. Let’s analyze a high-strength metal bolt (Grade 8.8) with a diameter of 10mm. This bolt is subjected to a tensile load of fifty kN.

Steps for Calculation:

- Materials Properties: Get hold of the yield power worth for the required bolt grade (Grade 8.8) from a good materials knowledge supply. For Grade 8.8 bolts, the standard yield power is round 800 MPa.

- Cross-sectional Space: Decide the cross-sectional space of the bolt utilizing the method: Space = π

- (Diameter/2)^2. On this case, Space = π

- (10mm/2)^2 ≈ 78.54 mm 2.

- Stress Calculation: Calculate the stress on the bolt utilizing the method: Stress = Load/Space. Stress = 50 kN / 78.54 mm 2 = 636.6 MPa.

- Comparability and Conclusion: Evaluate the calculated stress to the yield power of the fabric. Since 636.6 MPa is lower than 800 MPa, the bolt is properly under its yield level and is predicted to carry out inside the elastic vary.

Calculating Yield Energy for a Totally different Bolt Sort

Analyzing the yield power of various bolt varieties requires consideration of assorted elements like materials composition, manufacturing processes, and meant utility. Let’s study a stainless-steel bolt (AISI 316) with a diameter of 6mm, beneath a shear load of 20 kN.

Steps for Calculation:

- Materials Properties: Seek the advice of materials specs to search out the yield power for AISI 316 chrome steel in shear. This worth may differ from the tensile yield power and is usually decrease. Assume a shear yield power of 250 MPa for this instance.

- Cross-sectional Space: Calculate the cross-sectional space utilizing the identical method as earlier than. Space ≈ 28.27 mm 2. Notice that the world utilized in shear calculation could also be totally different relying on the bolt geometry.

- Shear Stress Calculation: Calculate the shear stress utilizing the method: Shear Stress = Shear Load / Space. Shear Stress = 20 kN / 28.27 mm 2 ≈ 707.5 MPa.

- Comparability and Conclusion: The calculated shear stress (707.5 MPa) exceeds the assumed yield power (250 MPa). This implies that the bolt will probably yield beneath the utilized shear load. A redesign or discount in load is critical to make sure the bolt’s structural integrity.

Actual-World Engineering Downside

In a bridge building undertaking, the security of the connection between the supporting beams and the deck is essential. The bolts connecting the parts should face up to the dynamic hundreds induced by site visitors and environmental elements with out yielding. Correct calculation of bolt yield power is crucial for making certain the structural integrity and longevity of the bridge.

Bolt Yield Energy Underneath Numerous Loading Situations

Bolt yield power is not a hard and fast worth; it varies with totally different loading circumstances. Take into account these:

- Tensile Loading: The most typical loading situation. The tensile load immediately influences the stress on the bolt.

- Shear Loading: The load utilized parallel to the bolt’s cross-section. Shear power is commonly totally different from tensile power.

- Mixed Loading: A mix of tensile and shear forces. The mixed impact should be evaluated. Advanced calculations typically require numerical strategies or software program instruments.

Stress-Pressure Relationship

Understanding the stress-strain relationship for various supplies is essential in figuring out bolt yield power. The connection dictates how a lot stress a fabric can face up to earlier than yielding.

Stress-strain curves present a graphical illustration of this relationship.

| Materials | Stress-Pressure Curve | Yield Energy |

|---|---|---|

| Metal | (Illustrative curve exhibiting a transparent yield level) | (Worth representing the yield level) |

| Aluminum | (Illustrative curve exhibiting a gradual yielding) | (Worth representing the yield level) |

| Titanium | (Illustrative curve exhibiting excessive power and stiffness) | (Worth representing the yield level) |

Bolt Materials Choice

Deciding on the suitable bolt materials is essential for making certain the structural integrity and longevity of your mechanical assemblies. The chosen materials should not solely meet the required yield power but additionally face up to the particular environmental circumstances and operational stresses. Selecting the right materials can stop pricey failures and guarantee a strong and dependable design.

Standards for Materials Choice, Tips on how to calculate bolt yield power

Bolt supplies are chosen primarily based on a large number of things. Yield power is paramount, however different essential concerns embrace corrosion resistance, fatigue life, and cost-effectiveness. The precise utility dictates the optimum materials selection. A fabric that excels in high-temperature environments will not be appropriate for corrosive environments.

Components to Take into account in Materials Choice

- Yield Energy: The first driver for materials choice, because it dictates the utmost load the bolt can maintain with out everlasting deformation. This should be adequate to deal with the anticipated hundreds and stresses within the utility.

- Corrosion Resistance: Environmental elements like moisture, chemical substances, and salt can considerably have an effect on a bolt’s lifespan. Supplies with inherent corrosion resistance or these that may be coated to boost resistance are very important for long-term efficiency.

- Fatigue Energy: Repeated loading, even under the yield power, can result in fatigue failure. Supplies with excessive fatigue power are essential for purposes subjected to cyclical stresses.

- Ductility: The flexibility of the fabric to deform plastically with out fracturing. Ductile supplies are sometimes most popular for his or her capability to soak up power throughout impacts and forestall sudden catastrophic failures.

- Value: The financial side is all the time thought-about. The price of the fabric needs to be balanced towards the yield power necessities and different essential elements.

- Workability: The benefit with which the fabric might be threaded, minimize, or fashioned into the specified form.

- Temperature Resistance: For top-temperature purposes, particular heat-resistant alloys are required. This issue is essential for sustaining the integrity of the bolts beneath excessive circumstances.

Bolt Materials Examples and Yield Strengths

A big selection of supplies are used for bolts, every with its personal set of properties. The next desk presents just a few examples, highlighting their respective yield strengths:

| Bolt Materials | Typical Yield Energy (MPa) | Purposes |

|---|---|---|

| Metal (AISI 1018) | 200-300 | Basic-purpose purposes the place reasonable power is adequate. |

| Alloy Metal (AISI 4140) | 600-800 | Purposes requiring larger power, like heavy equipment and significant structural parts. |

| Stainless Metal (304) | 200-300 | Purposes in corrosive environments. |

| Titanium | 400-900 | Excessive-strength, low-weight purposes like aerospace and demanding industrial environments. |

| Inconel | 600-1000+ | Excessive-temperature and high-strength purposes, together with aerospace, chemical processing, and energy era. |

Deciding on the suitable bolt materials is a essential choice, immediately influencing the efficiency, security, and cost-effectiveness of a design.

Particular Bolt Materials Purposes

- Metal Bolts (AISI 1018): Frequent on the whole building, mild equipment, and meeting purposes the place reasonable power is adequate. The decrease yield power in comparison with alloy steels means they’re extra reasonably priced.

- Alloy Metal Bolts (AISI 4140): Utilized in purposes demanding excessive power and resistance to deformation, reminiscent of heavy equipment, bridges, and structural parts. Their excessive yield power gives superior efficiency in demanding purposes.

- Stainless Metal Bolts (304): Most well-liked in environments with excessive corrosion, like marine purposes, chemical processing crops, and meals processing tools. Their inherent corrosion resistance makes them perfect for these environments.

- Titanium Bolts: Utilized in aerospace purposes and demanding industrial environments. Titanium’s excessive strength-to-weight ratio makes it appropriate for purposes requiring excessive power and low weight.

- Inconel Bolts: A standard selection in high-temperature purposes, reminiscent of jet engines and chemical processing tools. Inconel’s distinctive high-temperature power and resistance to corrosion make it appropriate for excessive circumstances.

Epilogue

In conclusion, calculating bolt yield power is a multifaceted course of requiring cautious consideration of fabric properties, manufacturing processes, and design specs. This information has offered a complete overview, equipping you with the information to confidently sort out varied engineering challenges involving bolt power. Keep in mind, precision in calculations and adherence to requirements are key for profitable outcomes.

Frequent Queries

What are the widespread varieties of bolts and their typical yield power ranges?

Totally different bolt varieties have various yield strengths. A desk summarizing widespread varieties and their typical ranges will probably be included in the principle content material.

How does warmth remedy have an effect on bolt yield power?

Warmth remedy processes can considerably alter the microstructure of the bolt materials, impacting its yield power. The information will clarify the particular results intimately.

What’s the position of security elements in bolt design?

Security elements are essential in bolt design to account for uncertainties and potential variations in loading circumstances, making certain the bolt can face up to anticipated stresses with out failure. The information will elaborate on this matter.

How do I account for bolt geometry in yield power calculations?

Bolt geometry, together with diameter, size, and thread configuration, immediately impacts the stress distribution and, consequently, the yield power. The information will illustrate easy methods to incorporate these elements into calculations.